As Covid lockdowns started to ease up, Fictiv’s leadership wanted to do a team build project to bring people back together. They decided on converting a 1956 Fiat 500F into an electric vehicle, with me managing the entire project. Over 20 members of the company ended up contributing to this project, with everything to from selecting the motor to fabricating battery boxes to making a custom dashboard insert for the fuel gage to documenting the whole project. For me personally, this was a great project for flexing a lot of muscles I hadn’t in a while. I got to act as a design engineer, teacher, safety officer, mechanic, machinist, technician, and electrician, and in the end delivered a presentation to the company about how we made a functional electric car on time and under budget.

Below are links to the official writeups of the project, as well as some additional images from the build.

Back when trunks were literally trunks

the original 14 HP engine

the gas tank was originally under the hood, but where we're going, we don't need gas

the beginning of my very long acquaintance with the transaxle

mocking up the trunk layout with the high tech tools of...

carboard, foam core, and 3D prints

one of the three Tesla battery packs that would make up our 72v, 16 kWh traction battery

the Edison plug that our battery charger came with would require some creative problem solving down the line

The 30 HP that was the heart of this build, and a big upgrade on the 14 HP this car originally had

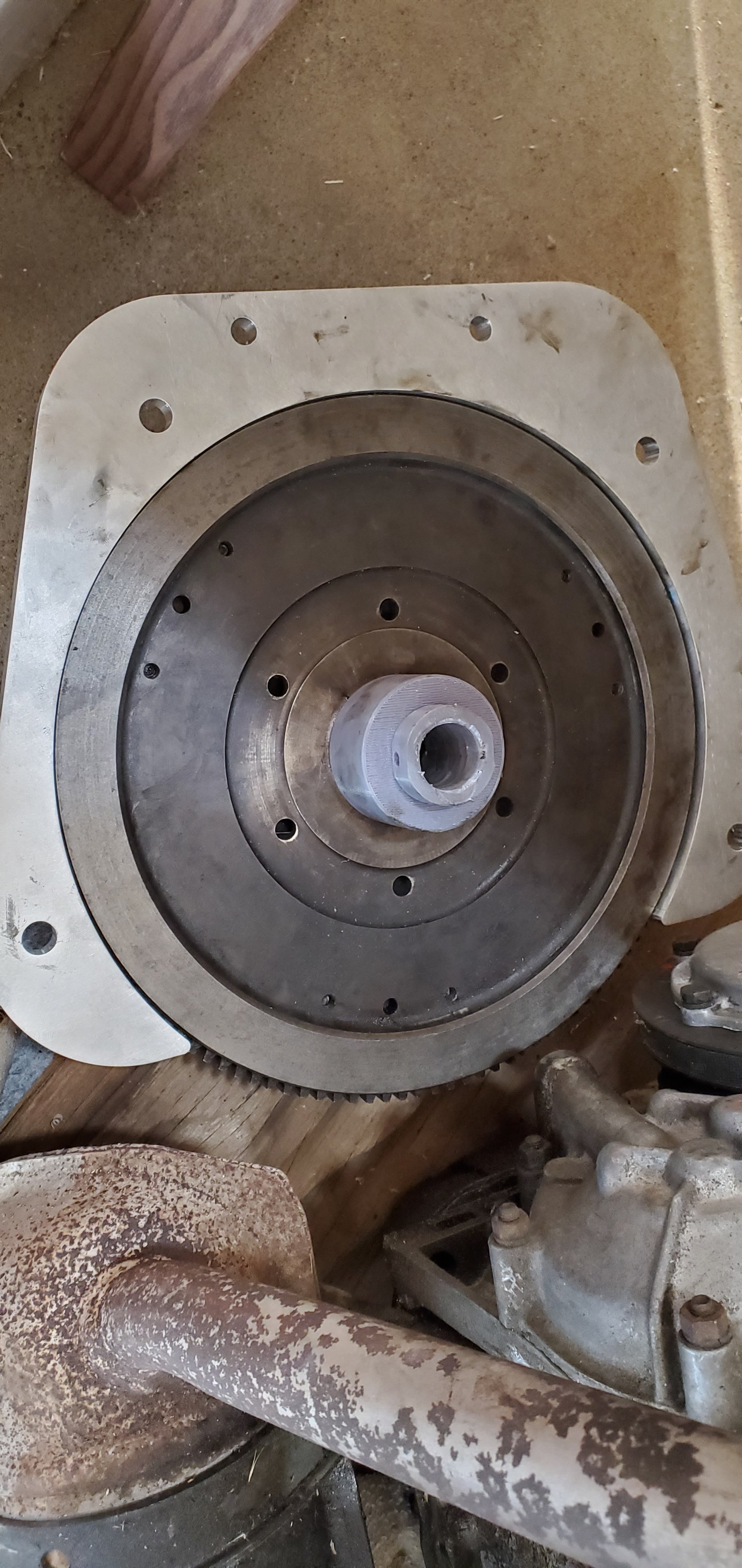

disassembling the clutch to reverse engineer the size of the housing

extreme CAD (cardboard aided design)

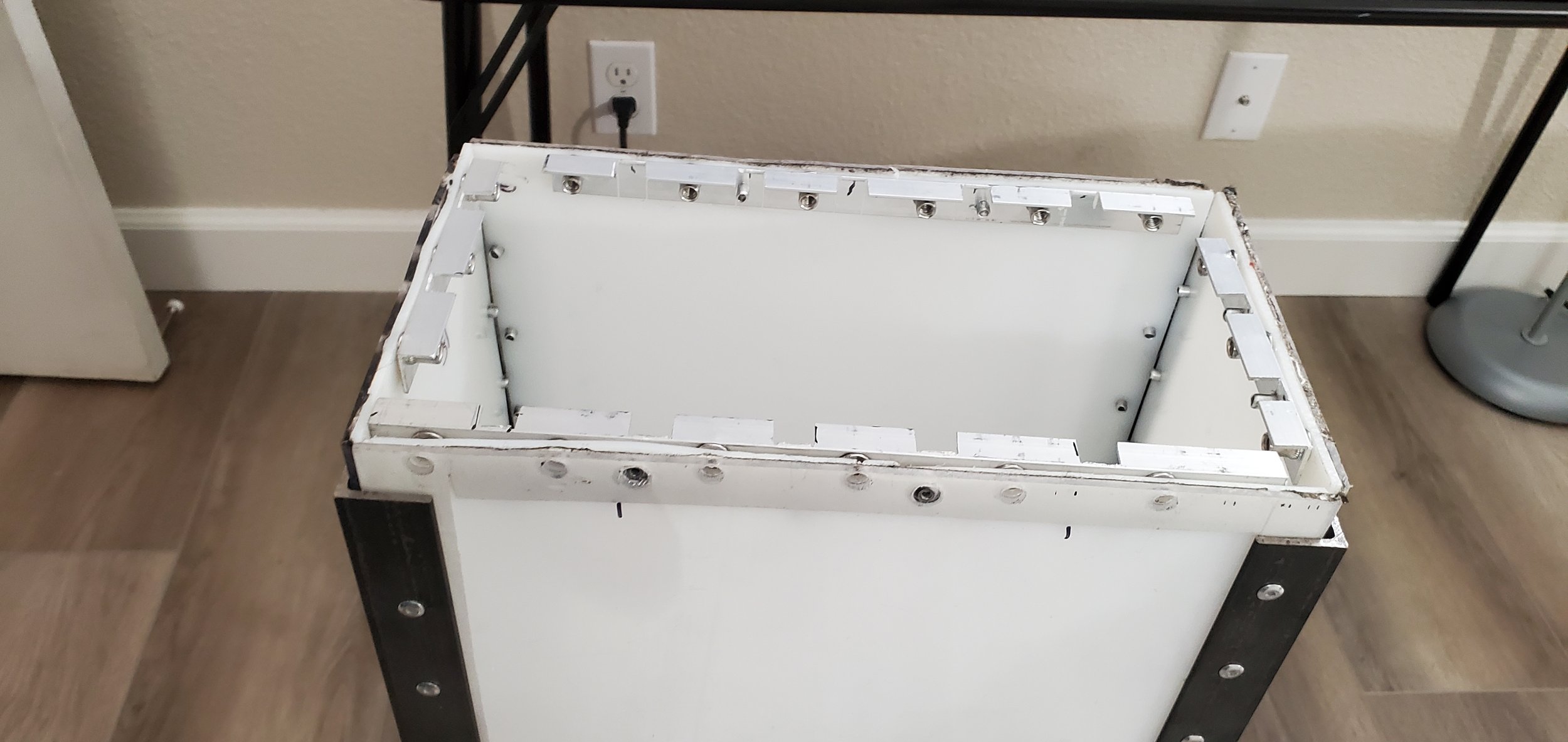

our two battery enclosures were made from steel angle for structural strength, polycarbonate for impact resistance, HDPE for cushioning, and a lot of rivets to hold it all together

so. many. rivets

the test fit that informed us a mistake on measuring the OD of the clutch meant I had to give the ID of our adapter plate some attention with a band saw and sanding drum

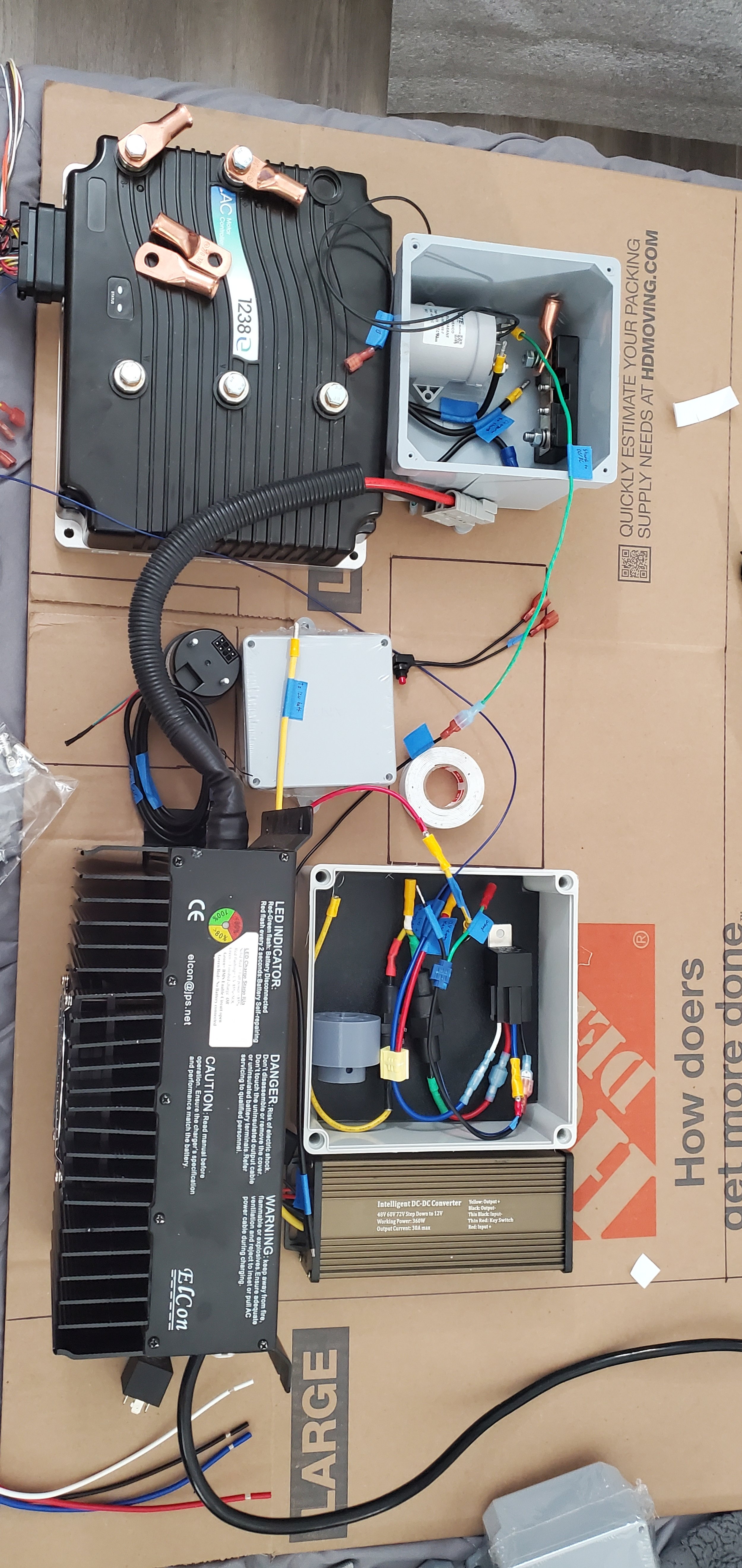

laying out the electrical part of the electric vehicle

enclosures and cable management to keep things visually and physically clean

the beautifully designed and color matched dashboard insert we made for the battery meter looks like it came with the car

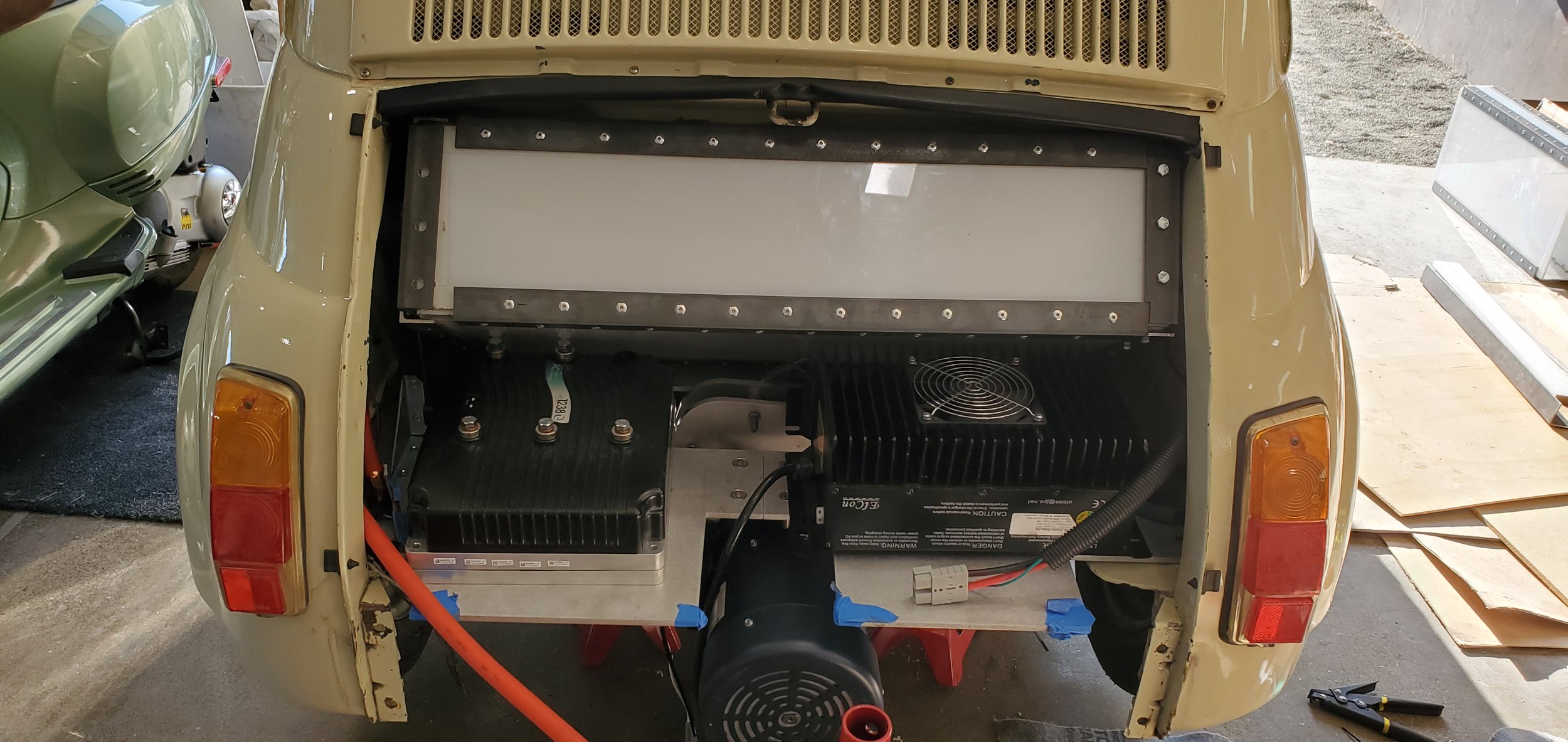

A lot of layout planning and a little elbow grease got everything to fit in the old engine compartment

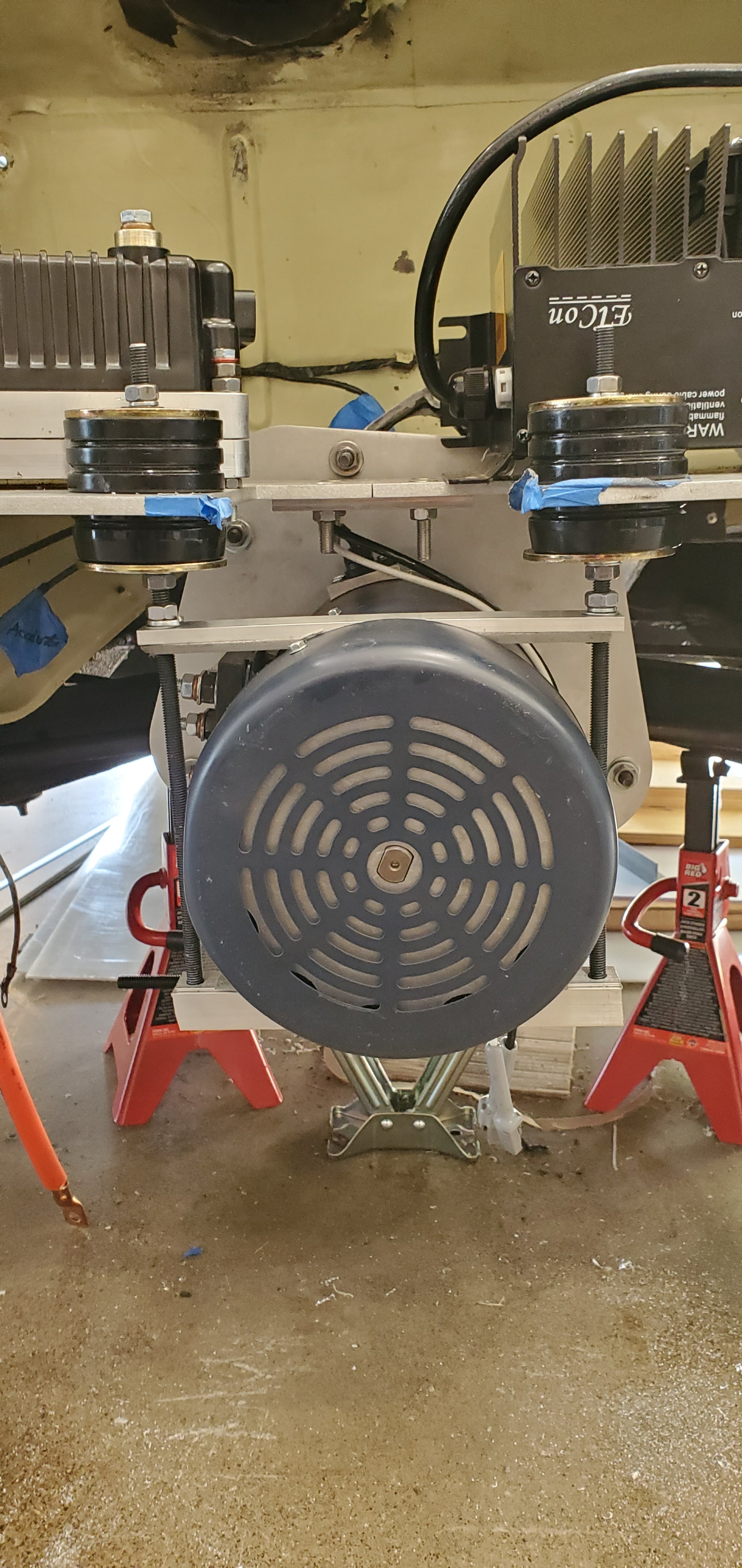

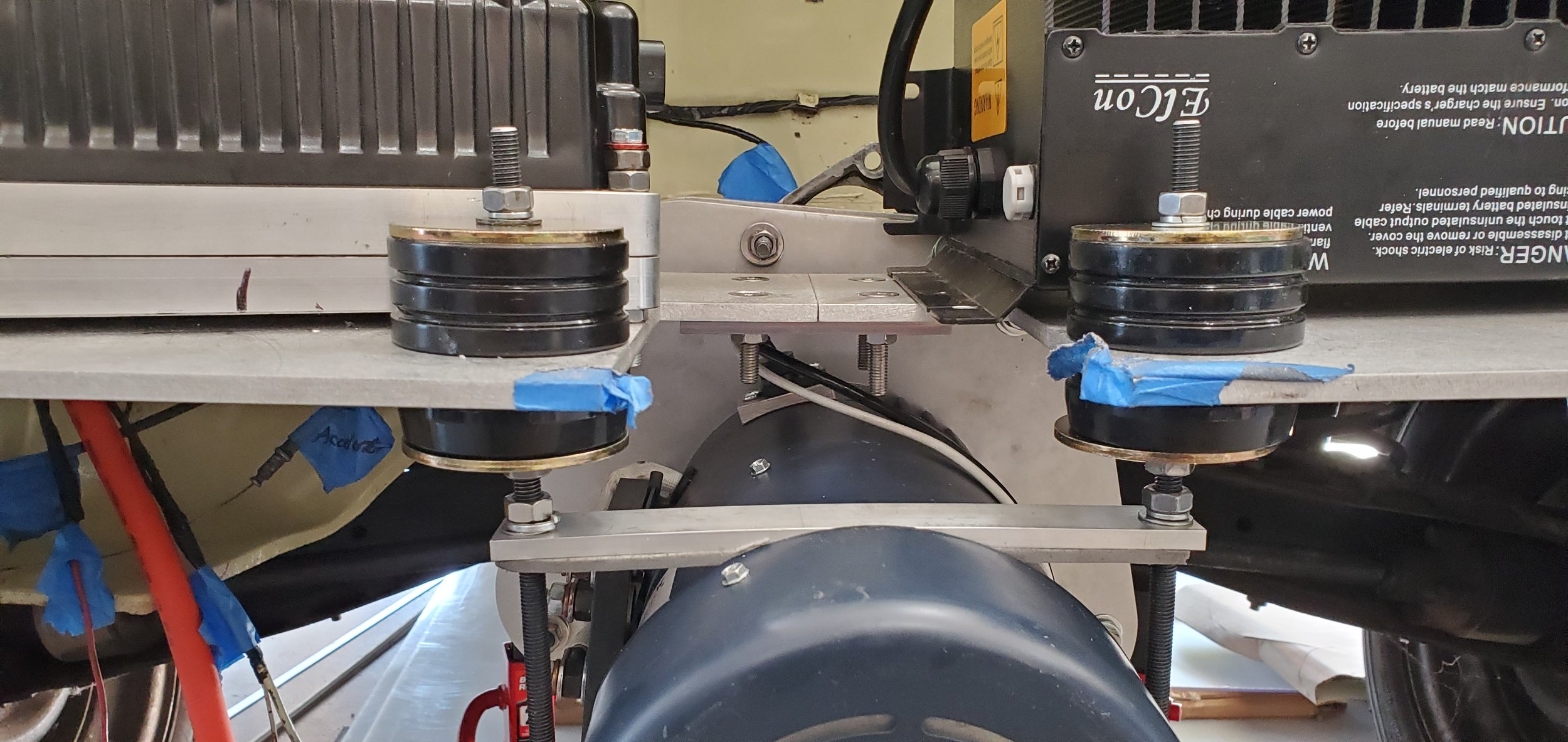

the final addition was a set of vibration dampers to support the motor

our tool crib manager after a long day of providing valuable assistance to the team